Drums

Information:

Information:

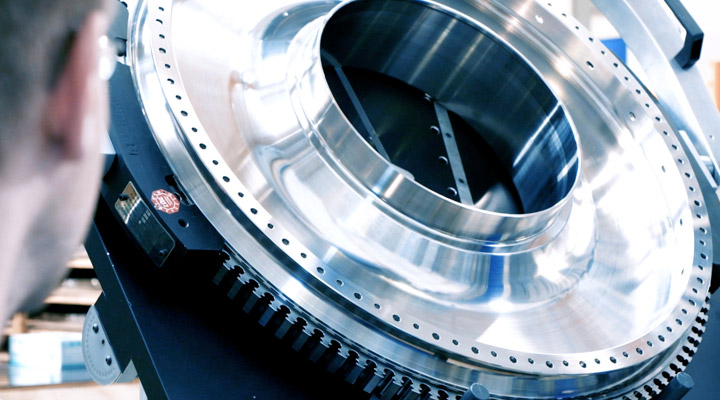

Thanks to the latest technologies in the field of turning and measuring technology, Aerotech Peissenberg has the manufacturing expertise to manufacture drums for high-pressure compressors and turbines.

Areas of use:

Areas of use:

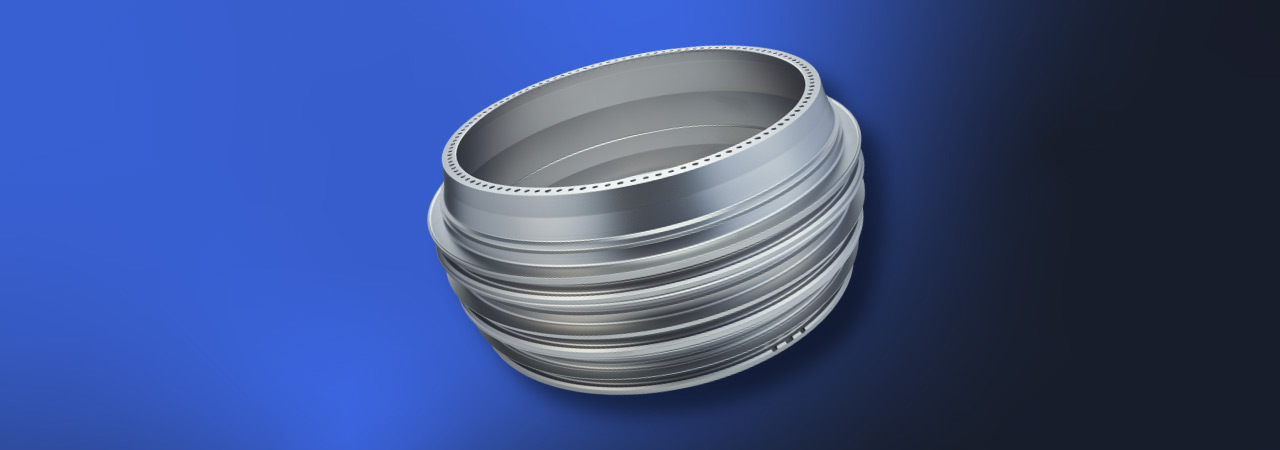

The term “drum” means the cylindrical or conical core of a drum rotor and it is made of titanium or high-strength Ni alloys. Several rows of blades are mounted on the drums. Torque is transmitted to each stage of the engine through the wall of the drum.

Manufacturing:

Manufacturing:

The manufacturing technologies used include the latest broaching and turning technologies (including ring groove turning) for the manufacture of blade connections and EB precision welding (EB = Electro Beam), a process group of fusion joint welding. Here, sub-segments of the drums can be connected using electron beam welding. The power density of the directed electron beam enables high welding speeds and weld seams of the highest quality. The savings in machining processes and excellent testability are characteristic of this technology, for which the latest measuring and testing technology is used: In-process measuring for the necessary process reliability, best fit for ring grooves and complex NDT testing processes (non-destructive testing) for quality assurance of material properties.