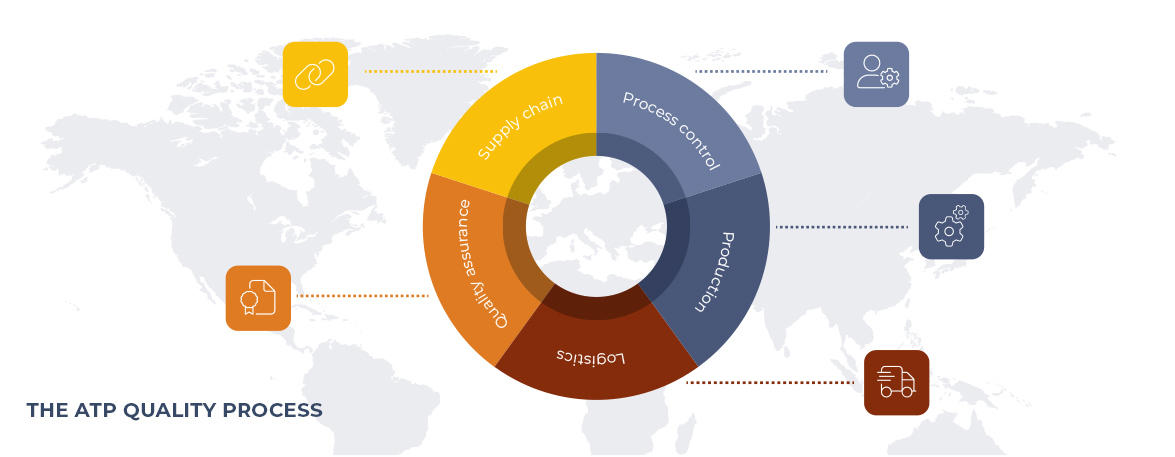

Our primary goal: Minimising risks.

We pay attention to every detail: Read here, how we are able to guarantee with our quality management robust precision machining, product quality and delivery performance from the start to the end.

1. Supply Chain

1. Supply Chain

One Stop Shop

The Aerotech Group has a global network of highly qualified suppliers and partners, who are regularly audited, developed and certified with regard to quality and sustainability. Our motto: Our customers should also be able to rely on those we rely on.

Upon request, we assume responsibility for the value supply chain management, which represents a significant relief for customers. This is why this service is ever more in demand.

We also supply special processes and testing procedures for forged and cast parts.

2. Process Control

2. Process Control

Value for money.

We stand for cost-efficiency and attractive conditions. For this, ATP continuously invests in innovation and the improvement of technologies and processes, as it is the only way to guarantee delivery performance and reliability in the future.

An innovative planning system, the latest production systems and a competent team of employees allow rapid product introductions (NPI), short production cycles with exemplary adaptability, leading to a maximum of transparency and delivery reliability.

We not only industrialise existing designs for our customers up to production readiness, but also support them during the product development process. As a result this production optimisation allows to avoid unnecessary costs and ensures an efficient serial production.

3. Production

3. Production

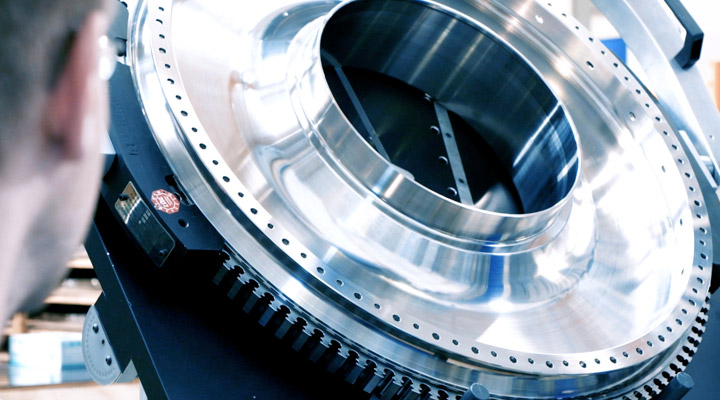

Nothing is impossible.

“Design on Demand” demands extreme flexibility. This is how we control production processes at the technical limit with our modern machinery and can even offer components in single piece production (batch size 1) – all with a high level of process stability.

We also assemble in-house produced parts with purchase parts into complex modules, as well as the integration of sockets, threaded inserts or connecting elements to create single finished assemblies.

4. Logistics

4. Logistics

Punctuality to the point.

To guarantee on time delivery to our customers, we assume full responsibility of the delivery process from the very start. This requires accurate planning for the best choice of logistics partners and the entire logistics flow for our deliveries. The advantage: short-notice changes are easily compensated and delivery remains “on time”.

5. Quality assurance

5. Quality assurance

No compromises.

ATP covers the entire range of quality assurance from the planning of the testing procedures to measuring components and from statistical process control to material testing in our own internal laboratory.

Our state-of-the-art EN9100-certified quality management systems is our foundation. This is as obvious to us as the seamless certification and approval by our customers. ATP also audits its own external service providers and suppliers including its certification to applicable standards.