Compressor Disks

Information

Information

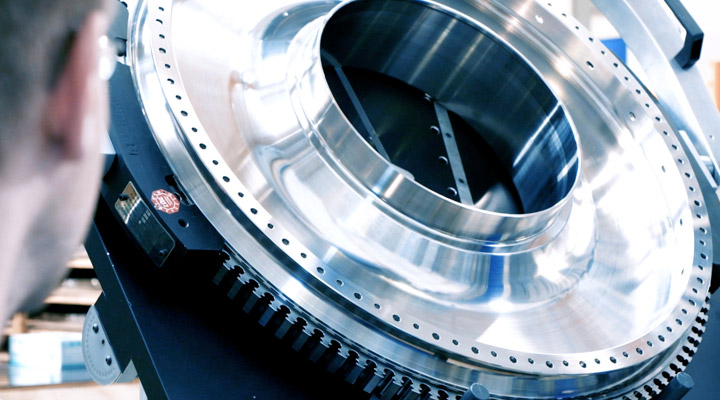

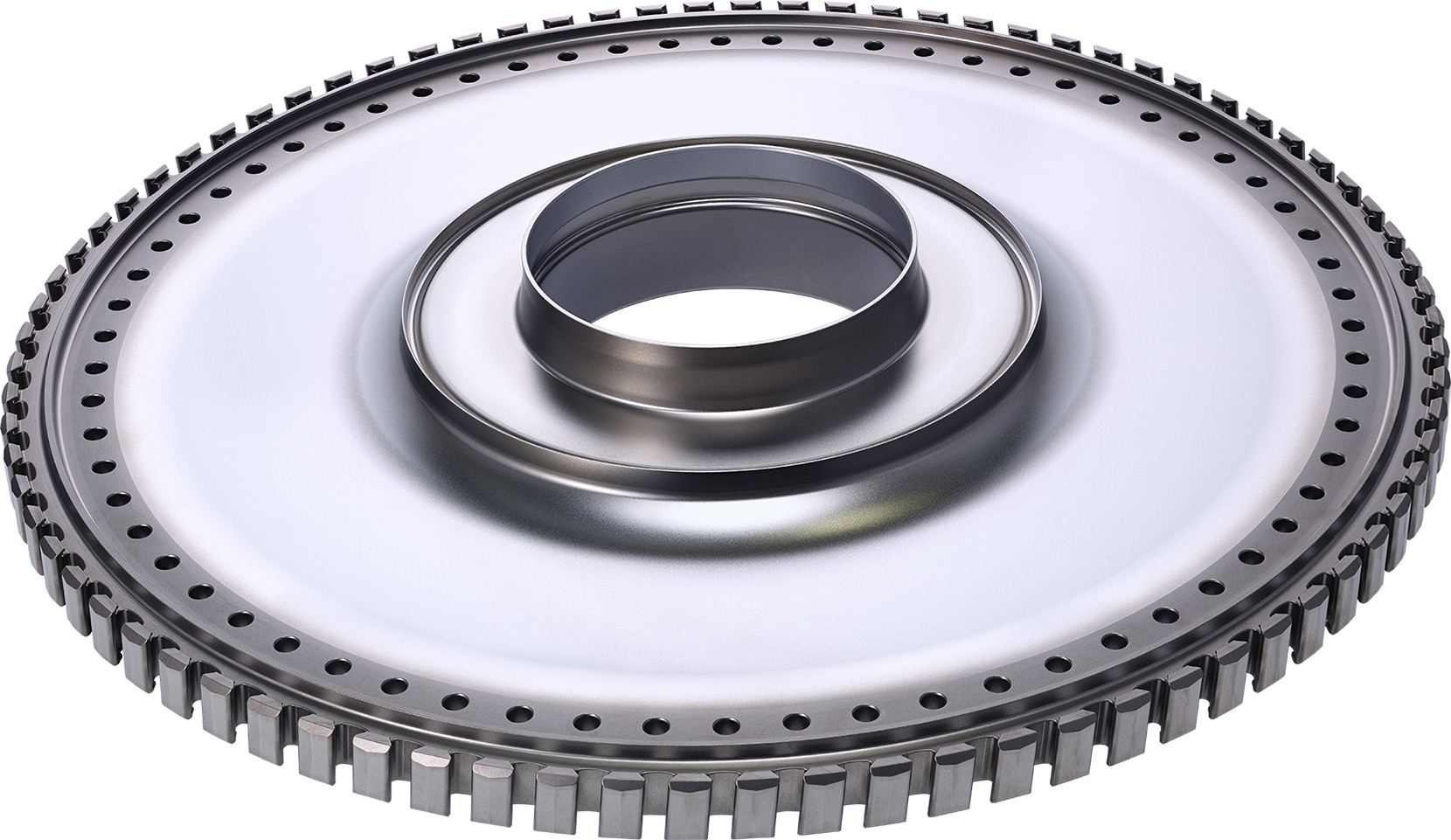

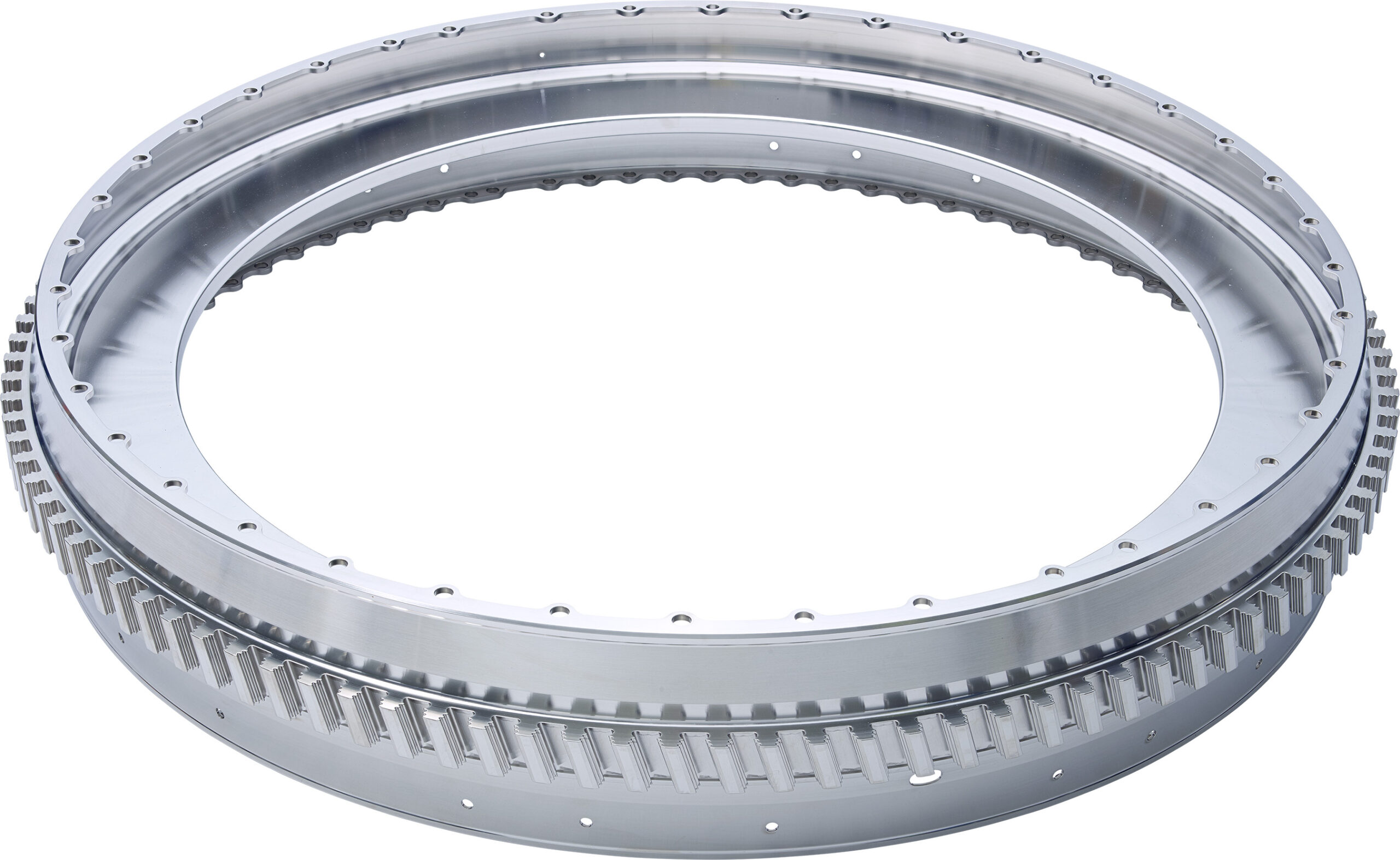

Compressor disks are among the highly stressed components in the engine, the highest precision and reliability are crucial in production. For this purpose, many different shapes and surfaces are precisely manufactured and assembled over several process steps. In addition, there are maximum requirements for surface quality and machining, such as roughness.

Areas of Use

Areas of Use

The generic term “compressor disks” includes a large number of similar components in the cold section of the engine (in front of the combustion chamber), which are permanently exposed to the highest loads. These include usually the low-pressure compressor (LPC) and the high-pressure compressor (HPC).

Manufacturing

Manufacturing

The main processing methods used here are cutting processes such as turning and milling, but also special processes such as coating, etching, shot peening and broaching. During broaching, a broaching tool is pulled through the disk in order to create the receptacles for the blades of the respective compressor disk. A very effective and high-precision process that produces even the most complicated shapes with the highest precision with just a single stroke.