We do not talk much about quality.

We produce it.

“Class 1” – this not only applies to the quality standard of our products, but it means for highly critical engine components: it is about peoples’ life. Consequently, at ATP excellence is not an option but a must and means a commitment to zero defects. The ambition for all our the work is to be performed with an uncompromised zero-defects strategy, which is constantly being monitored and optimised, and has made us over more than five decades a reliable partner in the international aviation industry.

Overview

Quality process

Quality from a single source – from the selection of our suppliers to production and quality assurance.

Find out more!

Production Philosophy

Constantly growing requirements in the aviation industry require the most modern production systems and concepts.

Find out more!

Downloads

Here you will find our official documents, certifications, information, regulations and much more.

Find out more!Our capabilities at a glance:

Engineering

of engine components for civil and military aviation and industrial gas turbines

Engineering

Production

of engine components for civil and military engines and industrial gas turbines:

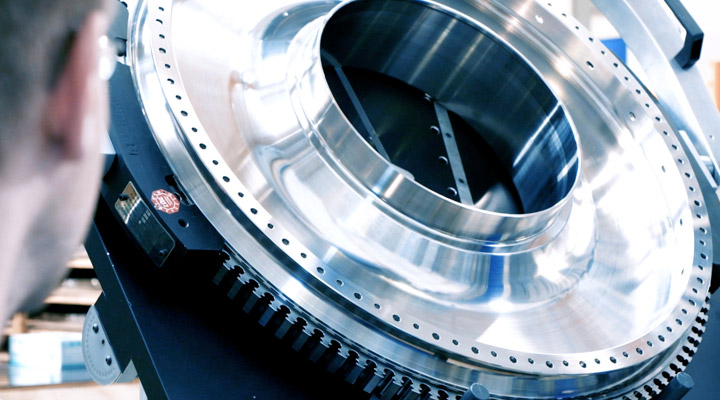

- Precision machining of compressor and turbine discs, drums, rotating /static rings and seals, casings/casing parts and other complex components (ø up to 1,250 mm)

- Coatings (plasma/HVOF)

- Macro Etching & FPI

Production

Material testing laboratory

for validation of technical requirements

Material testing laboratory

Quality management

EN9100 certified

Quality management

Supply chain management

From the procurement of materials to punctual delivery – the entire logistics from a single source.